Not known Details About DTF Transfers

Not known Details About DTF Transfers

Blog Article

just how long do DTF transfers last when they are pressed? Do they crack eventually? In the event your garment is saved in great condition (preventing severe climate and Bodily action), a normal DTF transfer can past for fifty+ clean cycles.

So when maybe you have A prosperous press of layered DTF transfers, the effects won't be as everlasting.

when you really are a primary STAR exemption recipient who turns 65 check here and fulfills the eligibility necessities, you must implement to the assessor for the improved STAR exemption. You merely need to apply as soon as. See STAR exemption application.

situation the print 3″ down from the collar for maximum effect. Pro tip: equilibrium the design which has a left chest print about the entrance for your coordinated look.

given that we know very well what DTF heat transfers are, Enable’s discover the benefits they offer for your online business.

As we’ve observed, Direct-to-movie transfers present a number of pros for enterprises planning to grow and reach now’s competitive Market.

DTF transfers present an remarkable alternate to standard approaches like screen printing and Direct-to-Garment (DTG) printing whether you are new to printing or a seasoned Skilled planning to investigate new tactics.

four. Curing: The movie is then cured using a warmth push or oven. This action is crucial because it makes certain that the adhesive solidifies and the design is ready to be transferred.

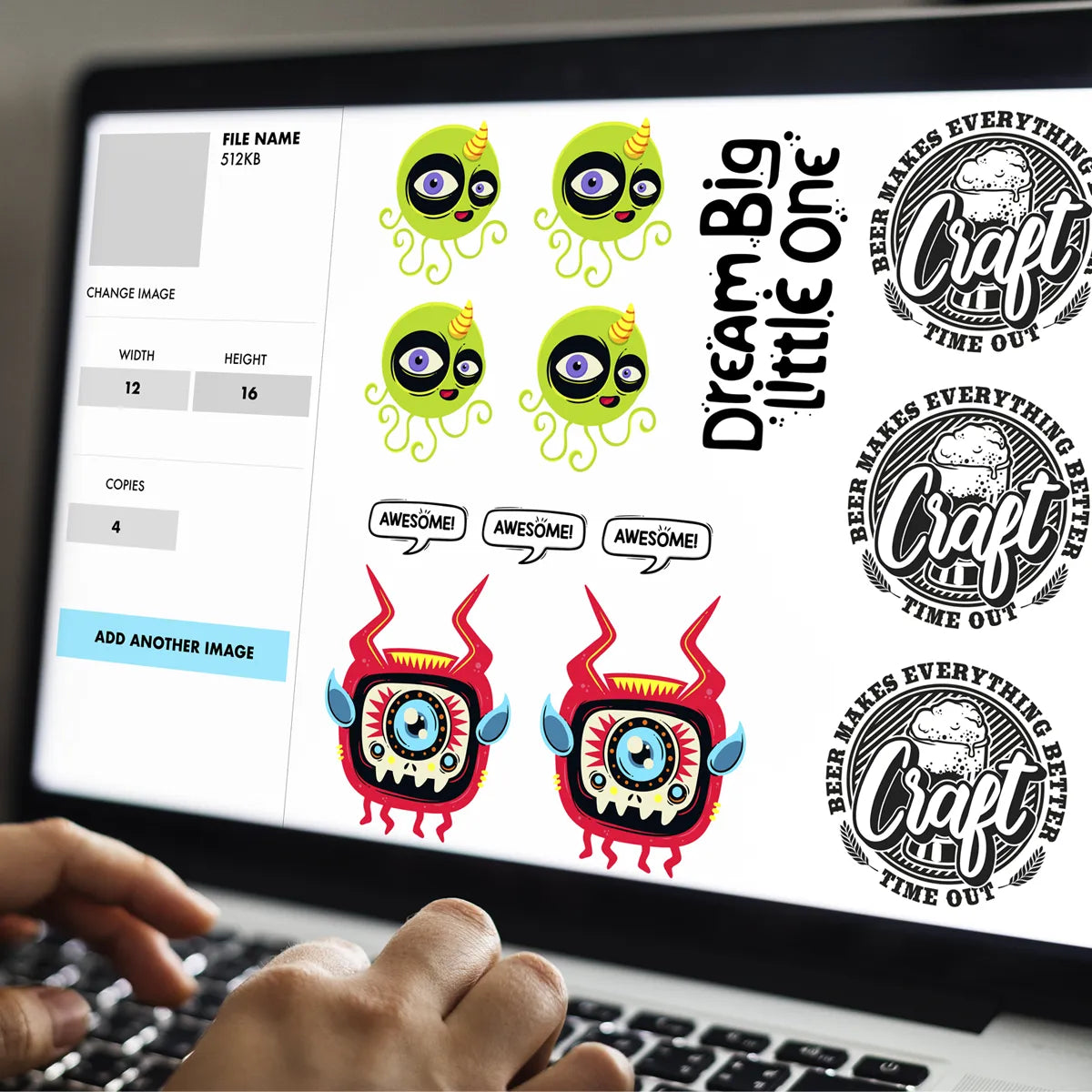

With wanting to push DTF Transfers, you can speedily and easily use Skilled-top quality models to your clothes, earning them an excellent Option for each beginners and skilled creators.

prior to we dive into the main advantages of DTF warmth transfers, Enable’s to start with determine what they are. DTF warmth transfers really are a type of heat transfer know-how that enables you to print large-quality, total-colour patterns straight on to a transfer movie, which can then be heat pressed on to a garment.

renovate your textile printing abilities nowadays with our unmatched DTF printing equipment selection and witness the extraordinary influence of condition-of-the-art immediate to film printer know-how on your company.

the method entails printing a design and style onto a selected movie, applying a powder adhesive, and afterwards warmth-urgent the design on to the fabric.

This printer utilizes drinking water-dependent CMYK and white pigment inks to print the look in reverse. The white layer is printed very last as a backing layer. This would make the colours around the substrate seem added vibrant.

future, you have to feed your style in the DTF printer. The DTF printer takes advantage of inkjet technologies to transfer the look on to a PET film.

Report this page